This article reflects need of electrical safety systems and prevention of electrical accidents at construction project

Why Electrical Safety is required for construction project ?

Electricity is the major source to run construction activities, machinery etc. It carry major hazard which may lead to serious accident like electrical shock, electrocution, electrical burn, fire & explosion, property damage etc. As per data from Central Electrical Authority (CEA), 13855 numbers of electrical related accidents happened in the year 2021 -22 all over India.

Therefore, Electrical Safety is a serious concern for all types of industries and construction projects due to its hazards and consequences. By prioritizing electrical safety, businesses can ensure safe completion of their construction projects as well as the safety of workers.

Common Electrical hazards in construction sites

Workers are exposed to different electrical hazards during construction activities through equipment & machines operation, electrical maintenance work etc. These hazards have potential to cause harm to human life.

Therefore, it is essential to identify, assess and rectify below hazards to ensure electrical safety at workplace.

- Unauthorized Operation: Conducting electrical activities without proper authorization and competency is a serious concern of the construction industry which contributes to enhance chances to occur electrical accidents.

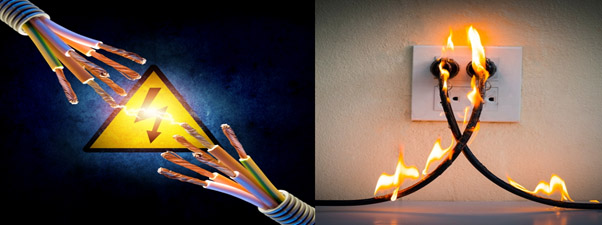

- Poorly insulated power cables: Damages in the power cables and contact with exposed wires may lead to electrical shock & electrocution and fire accidents due to short circuits.

- Trailing cables: Workers may fail to notice cables on the ground, especially in areas with low lighting, which may lead to accidental trips and falls.

- Improper earthing: Worker gets exposure of electric current due to unavailability of earthing arrangements or improper earthing for metallic parts of electrical appliances.

- Unavailability of circuit breakers: The electrical issues cannot be sensed and controlled without circuit breakers in electrical circuits.

- Overloading of electrical sockets: Plugging in too many electrical appliances beyond its capacity causes overheating and short circuit.

Control measures to prevent electrical accidents

Electrical accidents are top most serious concern of construction industry. Electrical accidents cause burn injury, electrocution, cardiovascular issues, damage to nervous system and other parts of human body.

Along with this electrical accidents causes major loss of properties. Therefore prevention of such accident through following control measure is need of construction industry to maintain electrical safety system

- Proper Insulation: Insulation refers to covering live electrical parts such as wires using nonconductive materials. Ensure insulation is provided in all electrical joints of exposed wires. It helps to prevent workers from electrocution due to accidental touch of exposed wires.

- Proper Routing of Cables: Routing overhead or underground not only prevents tripping and falling hazards, but it also prevents cables from getting physical damages. Wherever possible, always use conduits and cable tray to route the electrical power cables, especially in workmen accommodation.Protection Devices: Installing electrical protection devices such as Miniature Circuit Breaker (MCB), Earth Leakage Circuit Breaker (ELCB) and Residual Current Circuit Breaker (RCCB) in electrical system can prevent equipment from getting damages due to fire occurrence and prevent workers from electrocution due to fault current on metallic body of electrical appliances. Always use correctly rated protection devices and it shall be of good quality.

- Earthing provision: Ensuring earthing provision of all metallic parts of electrical appliances is essential to protect workers and will make low resistance path for fault current to flow into the ground. Inspecting earth pits and earth resistance value is important and ensure the resistance value (ohm) to as low as possible.Regular Inspection: Inspecting the electrical installations such as protection devices, power cables, distribution board is necessary to ensure its safe operation. Make sure the inspections’ results are within acceptable limits to protect the workers from electrical-related hazards.

- Training & awareness: Make sure workers handling electrical equipment are well informed about the hazards and risks through Safety posters, Toolbox Talk and campaigns. Workers shall be provided with regular training on Electrical Safety and evaluation post training shall be done to test the effectiveness of training.

- Personal Protective Equipment: Electrical rated Hand gloves and Safety shoe without steel toe shall be used by Electrician / Technician operating electrical panels and distribution boards to minimize the exposure of electrical hazards. Inspecting the hand gloves prior to use is essential to ensure adequate protection from hazards.

Conclusion

Electricity is the major type of energy required for construction activities. Major risks associated with electricity are electric shock/electrocution, short circuits and fire.

These risks can be minimized up to an acceptable level by understanding and implementing necessary electrical safety control measures, such as proper insulation, circuit breakers, cable routing, earthing, the use of electrical specific personal protective equipment (PPE), regular inspection and training & awareness.