GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

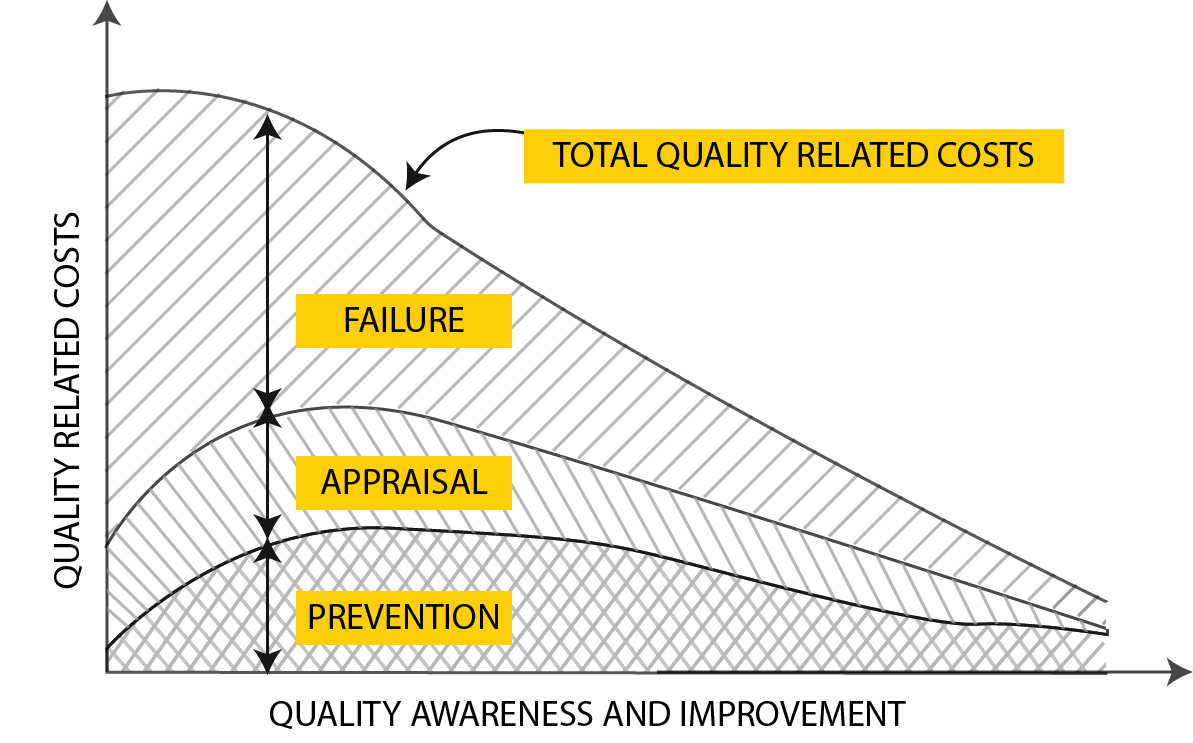

The literature of Quality Management is full of principle of ‘Cost of Quality’. However, few organizations have been able to put in place a cost-effective mechanism to measure and control the cost of quality (both cost of poor quality and cost of good quality). In the absence of hard numbers, leaders and managers are left with only an intuitive understanding about the cost-quality equation. Some are convinced that ‘quality is free’ or that investment in quality more than just pays for itself. Such leaders commit their organizations to invest in quality and reap the rewards. Some others lack a deep-seated belief about the positive effect of quality on cost and end up paying only lip service to the cause of quality.

If only managers and leaders had hard accounting numbers connecting the cost of prevention, appraisals and failures, the behaviour of leaders could be easily moulded in favour of preventive Quality Management. Juran, one of the foremost proponents of Quality Management believed it was important to directly link quality issues with costs. Linking quality, conformance and defects to dollars and profits was the only way to drive true change, thus unifying workers and senior management.

In the course of our interaction with decision-makers in the construction business and having observed the drivers of various decisions, both of strategic nature and mundane day-to-day decisions, we have seen that there are many occasions where there is a conflict between cost & quality OR cost & time. More often than not, managers choose cost over quality or cost over time. A few examples of such choices are listed below:

Experts and researchers who have studied the issue of Cost of Quality (COQ) have identified many benefits that can be realized from the use of information generated from a COQ measuring system:

Unfortunately, the benefits that are supposed to accrue are all intangible, uncertain and in the future, whereas the benefits of choosing cost/time over quality are all visible, immediate and certain in the limited context of direct cost! No wonder many succumb to the temptation of choosing short term benefit even at the risk of pain and problems later.

Unless the cost-quality trade-off is unequivocally established to be in favour of quality in long and medium term, the concept may remain attractive on paper but a non-starter on the ground.

GEM Engserv Private Ltd. , A-103, The Great Eastern Chamber, Plot No-28, Sector-11, CBD Belapur, Navi Mumbai 400614