GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

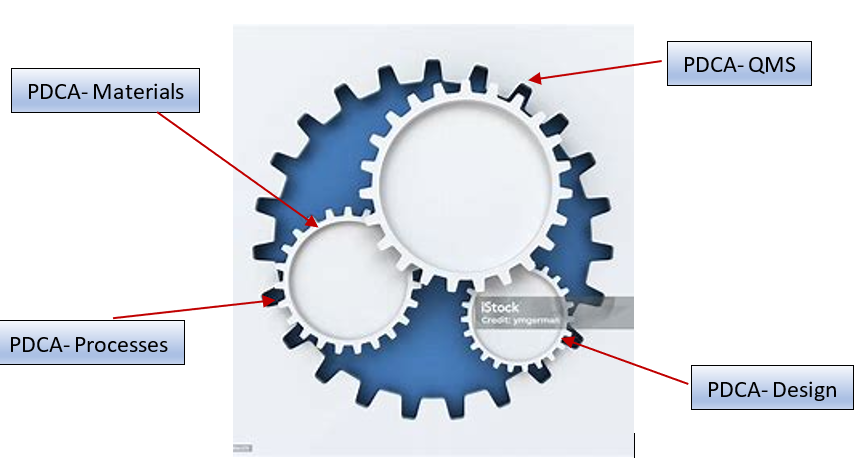

While many professionals in the field of Quality Management understand and believe in the PDCA (Plan-Do-Check-Act) cycle, its effective implementation is not very common. The PDCA cycle is not only to be applied to the QMS as a whole, it is also very effective in managing its individual parts. Conceptually, it looks like a set of wheels or gears within a large wheel or gear. The larger gear represents the PDCA applied to the overall QMS and the gears within representing the PDCA cycle applied to various components of the QMS!

The Plan-Do-Check-Act (PDCA) cycle is the backbone of Quality management System, the foundation on which the house of effective Quality Management is built.

In order to appreciate the depth and details to which PDCA cycle can influence outcomes, let us examine its application to one component of the overall Quality Management System, for example, to material testing.

Ensuring that all materials used in construction meet specific technical requirements entails elaborate planning and implementation of the plan. The document that lays down in detail, the inspection of materials is commonly known as Inspection and Test Plan (ITP). Let us see what each part of the PDCA cycle should mean in the context of Inspection and Test Plan (ITP) and whether the prevailing industry practices meets these requirements.

Plan: The plan part of PDCA of the material testing should involve the following actions

Do: While an effective ITP is an essential starting point, its implementation is equally crucial. Some crucial aspects are enumerated here for a quick self-check and assessment.

Check: Despite a well-documented and implemented ITP, it is possible that some inadvertent errors take place and either defective material gets consumed in the works or proper evidence is not placed on record about 100% compliance with the testing requirements. To check this, the most cost-effective method is to audit the entire process of testing of incoming materials. An audit conducted by an experienced Quality management professional can unearth gaps in the system of material testing. Our experience suggests that the following gaps often exist.

Act: The last part of the PDCA cycle simply means that the organization [Quality manager] responds to the audit findings promptly and eliminates the gaps identified. Different actions that typically emerge from a proper root cause analysis of the non-conformities identified by the auditor are listed below.

Drafting a Standard Operating Processe that brings together all stakeholders associated with material testing. These include the contractor, procurement department, quality team, execution team, billing engineer and planning engineer.

Needless to say, the Check and Act steps of the PDCA cycle should be implemented on a regular basis so that the system of material testing quickly reaches a near-perfect level. This requires engaging experienced auditors and responding to their findings in letter and spirit.

We hope that our readers, especially Quality Managers responsible for implementing the Incoming Material Testing process, are able to use this article for a quick self-assessment of their material testing system and take proactive measures towards continual improvement of this crucial element of the overall Quality Management System.

GEM Engserv Private Ltd. , A-103, The Great Eastern Chamber, Plot No-28, Sector-11, CBD Belapur, Navi Mumbai 400614