GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

The important element of having a successful structural construction is to have the right formwork system. That is, to have formwork system which has high trust and safety factor and is manufactured as per up-to-date technology available in the market.

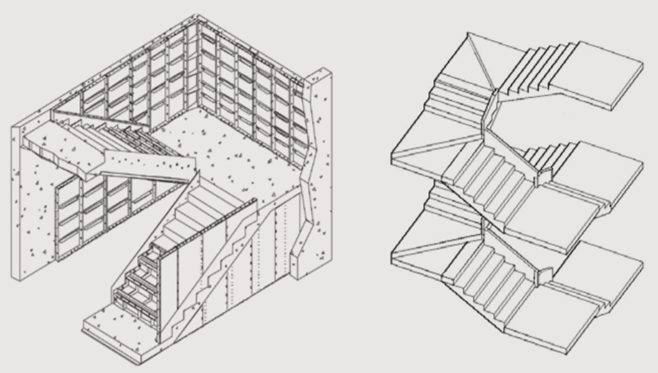

Alu-Form technology is used to produce high quality durable and affordable buildings. This technology incorporates electrical fittings, plumbing with greater efficiency as a part of overall building plan.

Hence, you should look for below characteristics to choose correct Formwork System for your project:

Trustful, Secure, Efficient, and Cutting-Edge technology.

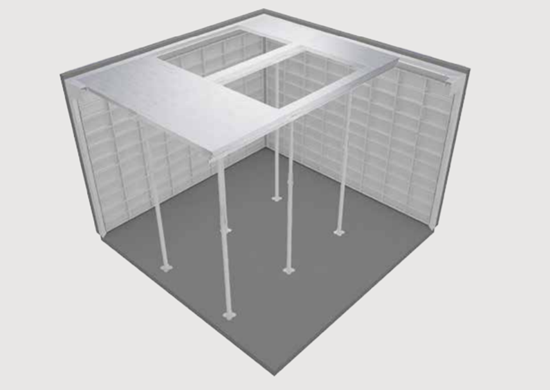

A good formwork is made up of high-strength aluminium extrusion which weighs very less compared to steel formwork. This technology helps to achieve more superior concrete finishing and quicker completion of project construction.

Below are the key benefits:

1. Improvement in Quality: The Aluminum Formwork technology results in good concrete finishing which does not require plastering and eliminates grinding task due to joints created by panels.

2. Ecofriendly: The best advantage of Aluform Technology is the repetition. The Aluminum panels can be recycled event after 250 repetitions compared to max repetition of 50 in Steel Formwork and about 5-10 repetition in Conventional Formwork. This ability to recycle results in less harm to the environment.

3. Reduction in Cost: As this technology requires assembly period of 6-10 days cycle, a Reduction in the construction period will directly result in reduction of cost of the construction.

4. Safety: The method of formwork system allows large working area for jobsite workers (with fewer props) and increase in their efficiency.

5. Design and Jobsite Planning: The Aluminum Formwork is a “modular” formwork; i.e. there is no constraint on any architectural or structural design.

To achieve the highest level of safety using the formwork system is to have correct supervision during erection and concrete pouring. The supervisors must be experienced enough to whether the formwork system is installed and assembled correctly. The formwork delivered on-site must be examined by the supervisor if it is manufactured as per the client’s design; So that no time is lost for installation and safety is ensured.

Chances of accidents will increase if the formwork materials are handled by inexperienced job site workers. i.e. Without adequate training using machines and equipment to handle heavy materials. Every supervisor must be involved in health and safety management system and in decision-making processes; Also, to understand and minimize risks and gain adequate control over health and safety.

GEM Engserv Private Ltd. , A-103, The Great Eastern Chamber, Plot No-28, Sector-11, CBD Belapur, Navi Mumbai 400614