GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

In couple of our previous articles, we have seen how Rebar detailing is beneficial to projects and why use of cut & bent reinforcement and Welded wire mesh are affordable engineering solutions. Rebar detailing helps enhanced production, wastage reduction, and superior quality.

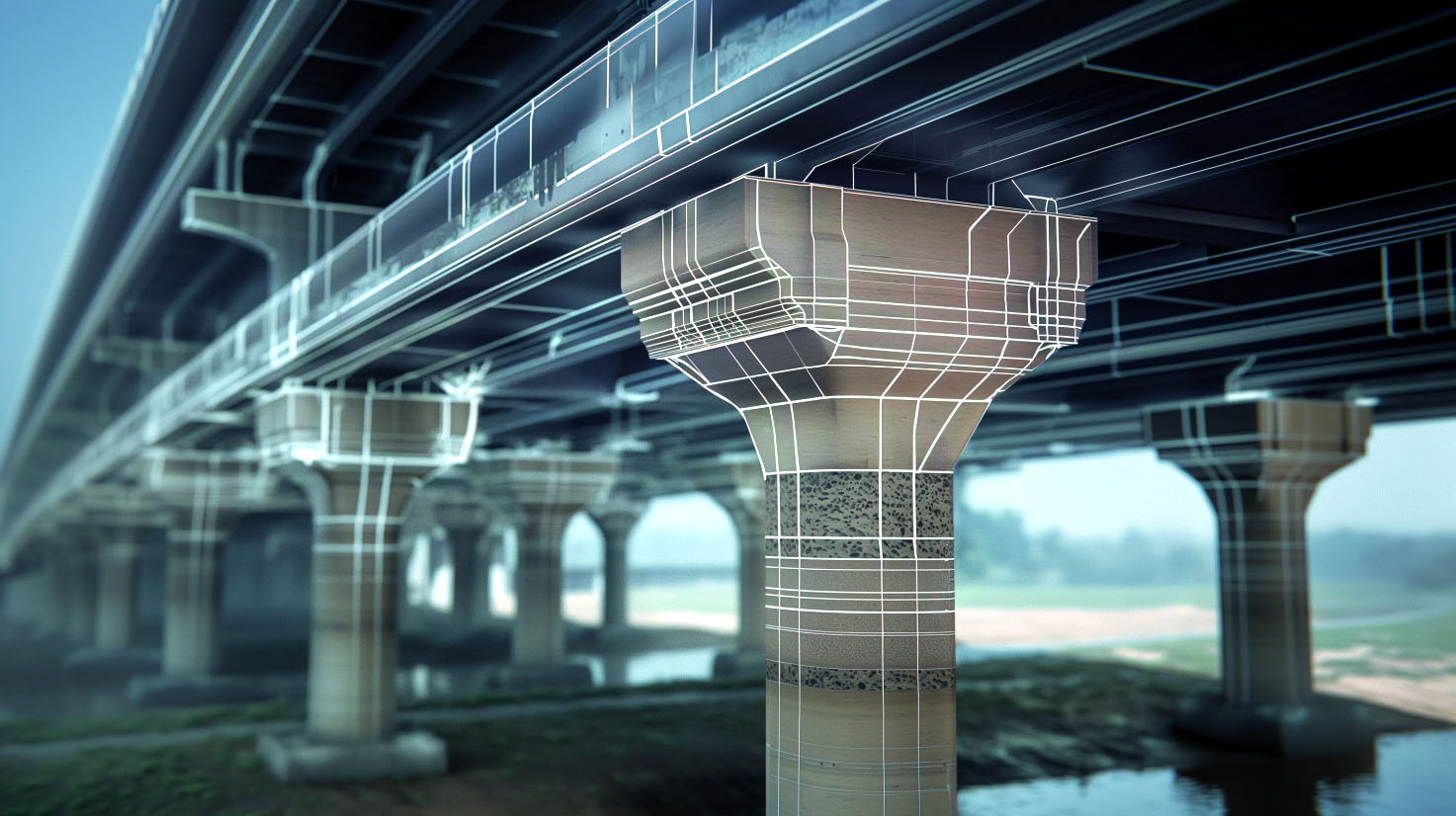

Additionally, it also saves “time and money” by early clash detection. Even though rebar detailing is done using softwares, it is still dependant on the experience & visualisation skills of the detailers and engineers, especially for large projects with densely reinforced and complex shaped elements. This is where 3D rebar detailing comes to the rescue of the project.

With more and more iconic structures coming up, 3D detailing is rapidly becoming a standard requirement.

3D Rebar Detailing is the process of preparing reinforcement Shop Drawings or Fabrication Drawings using 3D Modelling softwares. The reinforcement is modelled in the Structural Model, exactly as it will be placed on site and helps the site team visualise it in 3 dimensions. Whereas in 2D Rebar detailing, the detailer draws plan, elevation, section of the element. The reinforcement is drawn in the plan/elevation/section to make sure it fits within the concrete outline.

2D rebar detailing is a traditional way of working, that consumes lot of time and resources in large and complex projects. 3D Rebar detailing overcomes all the limitations of the 2D rebar detailing with clear cut advantages, listed below.

In this rapidly developing and increasingly competitive environment of the construction industry, 3D Rebar Detailing proves much helpful to enhance efficiency & quality of construction. It’s not only time saving but also facilitates proper Change management.

It provides a digital platform for collaboration amongst various stake holders like architects, designers, site engineers for creativity and innovation, while keeping the industry and safety standards in clear view. Construction companies can gain game changing positions in market, by releasing valuable resources due to significant time saving and pitch for newer projects to boost in their profit margins. By using 3D rebar detailing, companies can benefit from the adoption of new technology which modernizes their operations and ensures their survival & growth in the industry for the brighter future.

GEM Engserv Private Ltd. , A-103, The Great Eastern Chamber, Plot No-28, Sector-11, CBD Belapur, Navi Mumbai 400614