GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

Traditionally, in RCC construction projects, the management of reinforcement work (rebar) is done by setting up a storage yard, a cut & bend area, and locally shifting the cut & bend reinforcement for installation. However, due to the increased need for speed & quality coupled with limited space at construction sites, there has been a recent shift towards using factory cut & bend reinforcement. Despite this change, the installation effort required remains the same.

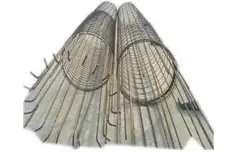

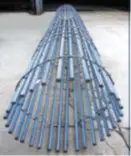

To address this constraint, a new technique has emerged called the use of prefabricated cages. Prefab cages are factory-made reinforcement solutions in the form of a cage, which facilitates the modular construction of structural elements on-site. These cages are manufactured using machines or jigs, controlled welding conditions by trained and specialized workers in a factory-controlled environment. This approach leads to cost saving, faster on-site installation, & improved safety.

Although the use prefabricated cages is not very popular in INDIA, it is widely adopted in developed countries like the USA, CANADA, SINGAPORE, UK, and the Middle East region. The popularity of prefabricated cages in these countries can be attributed to several factors, including shortage of labour force, limited working space and tight project timelines. In Metropolitan cities where space constraints make it challenging to set up cutting, bending and storage yards on-site, the adoption of this technique becomes even more crucial.

By utilizing prefab cages, site efficiency & productivity are improved, reducing the reliance on on-site manpower. Prefab cages can be positioned more quickly compared to placing individual bars and tying them in place. This results in reduced cycle time for slab casting.

When planned right from design stage, the use of prefab cages allows designers to optimize their utilization, leading to overall cost saving. Projects gain a competitive edge and experience reduced construction costs due to the enhanced speed of construction. Designers can optimize use of similar bar diameters across elements thus facilitating bulk procurements. By understanding and leveraging efficiency, cost saving, and improved timelines.

By conducting the cutting, bending and production of prefab cages in a controlled workshop environment, the use of advanced machines and techniques ensures consistent and high-quality results. The utilization of machines also contributes to greater dimensional accuracy.

The cutting & bending of rebars for prefab cage production can be done directly from rolls rather than using stock length bars, which significantly reduces wastage.

Production schedules can be optimized to maximize the utilization of available stock lengths & rationalize the use of rebars with similar diameter and lengths. This approach further reduces wastage.

prefab cages can be lifted directly from trucks and placed on location; eliminating the need for additional storage. This not only saves space but also minimizes issues like rusting and soil contamination, ultimately leading to high quality, more efficient and cost-effective construction processes.

By implementing these measures, construction projects can achieve improved quality control, reduced wastage, and optimized use of resources, ultimately leading to more efficient and cost-effective construction processes

Factory production is inherently safer as compared to cutting & bending rebar at site. Use of prefab cages reduces involvement of workmen at site, thus the risk to workers / engineers on site is also reduced.

GEM Engserv Private Ltd. , A-103, The Great Eastern Chamber, Plot No-28, Sector-11, CBD Belapur, Navi Mumbai 400614