GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

The story of Toyota’s meteoric rise in the automobile industry is widely known and credited to the Toyota Production System. They pioneered the lean production and management philosophy. A closer look at its history shows how this was an evolution over time; a tale of bleak circumstances, benevolent ambition, some difficult lessons, and an iron will to introspect and self-correct. Lean management has been emulated by several firms not only in automobile manufacturing but also across other industries. Construction, however, has been a laggard as usual.

In my interactions with a prospective customer, I was curious about their much talked about lean building practices. A quick couple of questions revealed that their claim to fame in this area was a state-of-the-art bricklaying robot which is six times faster than a bricklayer working on their own. While this brings about a large saving in bricklaying time, this activity itself may impact marginally to the critical path of project schedule. This firm is among the top three in their segment, and I was taken aback seeing that they had mistaken waste elimination for productivity improvement.

This piece highlights a few core principles of lean production and urges us to look at how we operate in the construction industry with respect to each of the points below.

Lean construction management recommends having a long-term, holistic outlook instead of localized view serving short-term goals. How often do we take decisions on our projects in anticipation of benefit a few months down the line rather than an immediate short-term gain? As an example, do we ever opt for a vendor that charges more for a superior product and how easily do we ourselves fall in the L1 trap? On similar lines, there is tremendous resistance in adoption of certain proven practices (3D modeling, offsite manufacturing) because the benefit from them accrues only a few months after implementation. Can you think of other instances at your own project where you have observed important decision being made with a limited, short-term view?

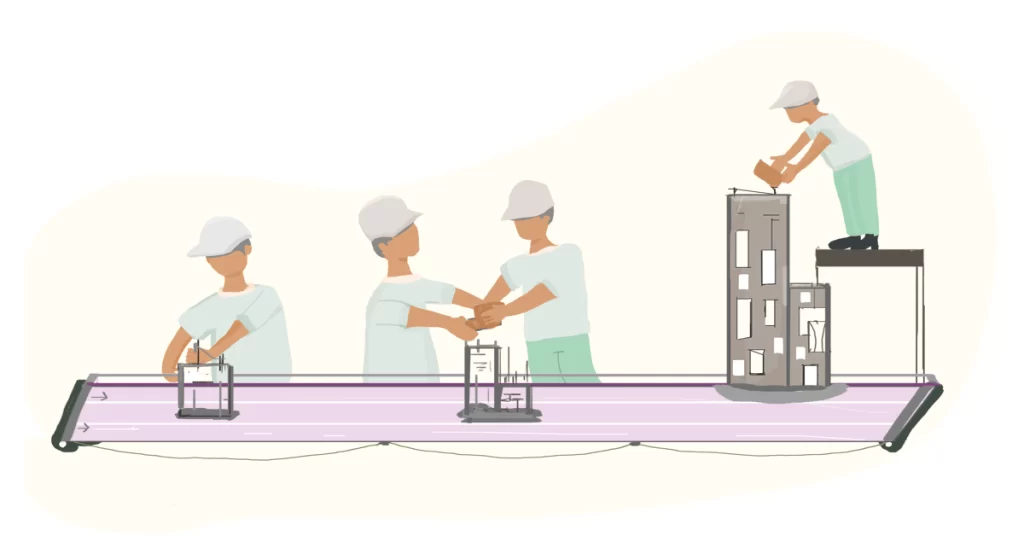

As per lean production principles, continuous process flow ensures that any deficiency in the system gets highlighted immediately. Consider building construction in this example. It is standard practice to commence finishing activities only after at least four next slab cycles are complete. Why is this so? Is there a reason for this “buffer” or is it due to our lack of confidence that subsequent slabs will be completed just in time? Lean construction would stipulate minimizing the time between these two phases so that the entire project team is focused on completing the slabs in time. Attempting this would also immediately point out the bottlenecks that need to be resolved to make the entire system more efficient.

We overproduce Work-In-Process (WIP) inventory. In this example, the four slabs that are cast and waiting idle are WIP. This is probably because we have never thought of adopting a pull mechanism in our project plans. A pull mechanism identifies customers for each process (external as well as internal) and recommends that a process (Concreting) should produce only as much WIP inventory i.e. completed slabs as demanded by its customer (Blockwork / Masonry / next in sequence). An appropriate safety stock should always be planned but we can all agree that five slabs is hardly the right amount of safety stock between these two processes.

As against the build-up of multiple slabs of WIP inventory, a smaller buffer of slabs works better in more ways than one:

Another extremely crucial step in lean construction project management is the relentless focus on preventing defect from reaching the customer. The system needs to be able to detect problems, stop itself and visually alert all stakeholders that a problem needs to be resolved. Thereon, all involved teams must come together to identify the root cause, implement immediate correction, and plan corrective action to prevent recurrence. Work should resume only after all teams agree on this outcome. This task of detecting-stopping-alerting is / should be performed by Quality Control (QC) personnel on construction sites. However, is the QC team empowered to stop work or do we override them because achieving the next milestone is essential? When was that last time on your project that QC was allowed to stop work, call for a root cause discussion and move forward only after all agreed on its resolution?

The emphasis on progress is so large that it crushes the attitude of stopping work and solving a problem. This practice amplifies defects because they are compounded as they pass on into the next process unresolved. The numerous cases of leakage, seepage and bulging during monsoons observed on impeccably painted walls points directly to a compromise on this practice. This attitude also demonstrates an approach of valuing short-term gain without visualizing the long-term pain that is in store.

The Toyota Production System incentivized doers instead of managers and this approach percolates into lean building practices as well. Team members who understand a company’s culture and philosophy and have spent days, weeks, months, years running standardized processes are able to identify root causes of issues more easily and even anticipate them before they occur. However, several firms in the construction industry have a practice of bringing in outside leaders to manage teams that have lived the culture. This often is a recipe for disaster, and we all know projects which have suffered for this reason.

In summary, lean principles are a set of commonplace, logical rules which seem too simple to be effective, yet pose a challenge during implementation. This may be because these principles try to address the most fundamental actions to which we never attribute any possibility of optimization. We need to re-engineer the most mundane, common actions that we undertake over and over again each day, instead of searching for a quantum leap in activities that we think are crucial.

PS: This piece can also be seen as a quick guide to practices that can be adopted in order to take the first steps towards implementation of lean construction principles.

GEM Engserv Private Ltd. , A-103, The Great Eastern Chamber, Plot No-28, Sector-11, CBD Belapur, Navi Mumbai 400614

Worth pondering