GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

GEM Engserv Pvt. Ltd is an ISO 9001:2015 certified organization, certified by TUV India in accreditation with National Accreditation Board for Certification Bodies (NABCB).

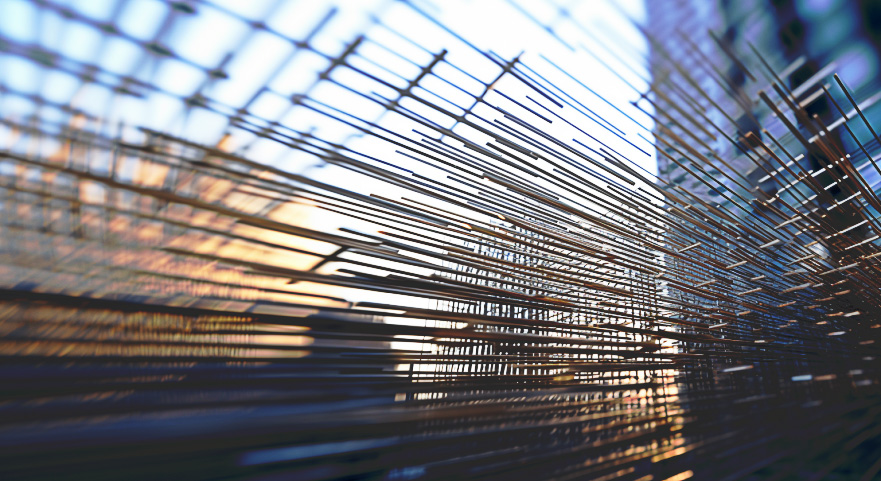

If you ask any project manager about the biggest pain area in the entire construction project, managing quality and quantity (wastage) of rebar on site is the default response for most. This is because of the way reinforcement is traditionally managed on our construction sites (cut and bent manually on site).

An alternative approach involves using reinforcement which is cut, bent and delivered from a factory. This model is proven to improve speed, accuracy, and installation quality (if done right). In congested metro cities, the space constraint at construction sites is another reason why this should be obvious. Despite these compelling reasons, we have not seen as big a shift to this off-site construction technique as we would expect.

As a means of addressing issues which prevent use of pre-cut and bent reinforcement, we have been constantly evaluating and suggesting other alternative techniques that we have come across while working for some of our international customers. One of these techniques is the use of Welded Wire Mesh (WWM), about which we have already written in the past. This has gained traction in markets such as the US, Canada, the UK, Ireland, Singapore where we support contractors and structural consultants with reinforcement detailing (or rebar shop drawings). This surge in adoption can be attributed to a limited availability of steel fixers (unlike in India) and a more organized ecosystem to enable adoption.

Crucially, the incorporation of mesh reinforcing finds support in the provisions outlined within Indian Standards. These standards offer guidance regarding the design and detailing aspects of WWM and affirm its viability as a reliable and standardized approach within the construction landscape.

For India’s current demand for mass housing and fast track construction, mesh reinforcement can emerge as a timely and essential innovation, especially in bustling metro cities. Our experience with mesh reinforcement detailing, and an observation of the actual fabrication process has allowed us to analyze the industry landscape and explore what will need to be done to bring about a change.

The relatively limited popularity of mesh detailing and offsite fabrication in India can be attributed to a lack of widespread awareness and understanding of its benefits. Designers and execution engineers are accustomed to traditional reinforcement methods and the comfort zone of their processes. Initiatives aimed at raising awareness and providing education about the benefits of this alternative is the first step. Workshops, case studies and collaboration across the industry can facilitate knowledge dissemination and drive a broader understanding of the potential of this technique.

Integrating mesh reinforcement into existing design practices and codes can be a hurdle. Designers and engineers need to recalibrate their approach to accommodate the unique characteristics of mesh reinforcement, such as its standardized dimensions and fabrication techniques. However, the challenge lies with the mindset and not with the provisions within the code.

Collaborative efforts involving architects, engineers, and designers can lead to the development of guidelines and best practices for incorporating mesh reinforcement into design plans. Designers will also need to consider the change in accessories and supporting infrastructure to ensure a smooth transition of the on-site processes. In the few instances when designers have tried to incorporate mesh reinforcement into their design, it has not been carefully considered from the perspective of the procurement and execution teams, which is why the experience of project teams with mesh reinforcement has been negative.

The effective utilization of WWM requires a certain level of technical expertise, from fabrication to installation. Acquiring the necessary skills and knowledge to handle WWM efficiently may pose challenges in regions where this technology is still new.

Training programs and skill development initiatives can bridge the knowledge gap. Structural engineering and project (execution) teams need to collaborate and align on the new parameters of fabrication, installation techniques, material inspection and quality control of the final assembly.

At present, the supporting ecosystem of manufacturing or fabrication units is nowhere near the capacity necessary to allow even a small-scale transition. If we are to leverage the true benefit from this technique, it would require ready availability of suppliers, the ability to produce custom mesh products, and the agility to scale up production in line with the demand. However, this is a typical chicken and egg case where adoption fails because of lack of supporting infrastructure and the infrastructure providers wait for the thought leaders to show faith in the new technique.

While thought leaders in this case are certainly the structural consultants, the real push for this radical approach can only come from the owners. Given the large upcoming demand for mass housing and an urgent need to ramp up construction, it is time that the custodians of the building industry explore this technique more seriously than ever before.